The many advantages of IQF Technology

The many advantages of using IQF Technology in your food products

Introduction

In this report, we’ll give you an overview of the basic advantages of frozen food over fresh produce, and what makes IQF technology stand out even more to deliver an incredible level of accuracy, flexibility, convenience, cost control and potential for innovation.

You’ll learn why a growing demand and interest in IQF products is registered at global level, and how your food company can take advantage of these extraordinary benefits to jumpstart your innovation trajectory, and get ahead of new market developments.

Frozen is fresher than fresh

The very fact that you’re reading this report means that you’re a professional in the food business, so this part will not exactly be like Breaking News to you. We’ll keep it short:

Produce quality begins degrading at harvest. Transport and processing takes time, but plenty of sellers put in the effort to deliver top-notch goods as fast as possible.

Despite these efforts, you’re losing money from the unpurchased, spoiled product, and the end customers are getting lower-quality fruits and vegetables than they would if they bought frozen produce: Freezing is just a way of putting nature on hold.

Besides, fresh products often need chemistry to keep the product look fresh. Acidifiers, stabilizer, preservatives… Frozen products don’t need any of that.

Although there was a time that frozen had a strong connotation with unhealthy fast food, consumers nowadays are much more savvy than previous generations: They’re really checking whether your labels are clean, and won’t fall for a great marketing story if that doesn’t match the content of your products.

The good news: They’re also aware that frozen products can be a lot better and more sustainable than fresh produce flown in from the other side of the planet because it’s out of season in their part of the globe.

Individually Quick Frozen: better than frozen

Faster is better

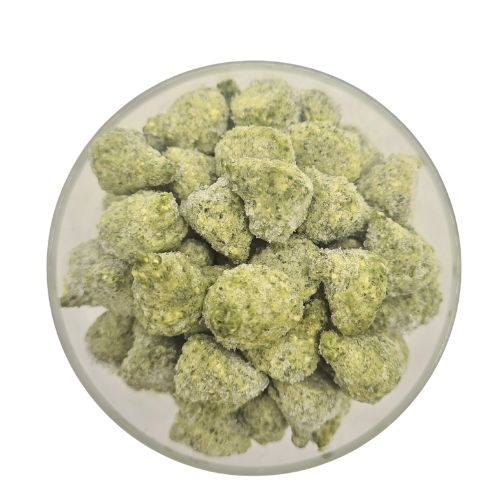

One of the main advantages of this method of preparing frozen food is that the freezing process goes incredibly fast, because we use liquid nitrogen at – 196 °C (− 320 °F): The drops literally freeze while they fall. That’s why you still see a drop shape in our pellets, even for ingredients with a very low viscosity like IQF lime juice pellets or IQF chlorella pellets.

The short freezing time prevents formation of large ice crystals in the product’s cells, which destroys the membrane structures at the molecular level. This makes the product keep its shape, colour, smell and taste after defrost, at a far greater extent.

Sustainability is key: Only defrost what you need

Since each piece is individually frozen, particles do not cohere. and the final product is not frozen into a solid block. This allows you to defrost what you need, and prevents leftovers going to waste.

Using IQF helps reduce packaging

Sometimes manufacturers individually wrap items before freezing, to avoid the conjoined chicken conundrum. While that does prevent food from sticking together, it’s time-consuming, an added expense in both labor and supplies, and an environmental problem.

It gets even better

Basic IQF: Frozen produce

In the basic form of IQF, the produce doesn’t get a treatment other than being washed and frozen. This is the case for small products like leafy greens, herbs, or berries. Bigger products, like vegetables, are also cut or sliced in smaller parts before they are individually frozen. This gives you all the advantages of IQF explained above, but it gets even better if we add one more process…

Advanced IQF: Puree or Juice into frozen drops

If we turn the produce into juice, paste or puree first, and then into IQF pellets, we open up a whole new world of possibilities:

The juice or puree is now sprayed onto a conveyor belt, and immediately frozen by the liquid nitrogen.

And now the fun begins: By adjusting parameters like pressure, the amount of product released, and the speed of the conveyor belt, we can actually start designing the drops.

Control your portions

The amount of product can be adjusted: It’s possible to make pellets of 2, 4, 8, 10… up to 20 grams in one drop! This dramatically reduces complexity in weighing and mixing processes.

Get in shape

Longer dispersal on a travelling conveyor belt results in a stretched shape instead of a compact drop, great for sauces or fillings in meat or veggie products. Having these ready in the shape you need makes it a lot easier to use them in your production.

Liquids become tangible objects

Liquids can be more difficult to manage than solid ingredients. If you work with juices, passion fruit pulp or coconut milk, you know exactly what we are talking about. Having these ingredients in tangible IQF pellets instead of liquids makes them a lot easier to handle and integrate into your products.

The other advantages still count too; No big drums with leftovers means less waste, and the specific weight of a pellet makes it very easy to add exactly 4 grams of any liquid into a dish or drink.

Control your cost: Doing it right becomes child's play

Imagine a pizza pesto, made in the kitchen of a restaurant, or in an industrial production line. Both examples need to achieve accurate dosing to keep the costs under control.

In the restaurant kitchen, the staff puts 8 IQF drops of 5 grams on a pizza, instead of using a piping bag with a big error margin. The level of control you get when working with IQF technology provides a high level of precision and reduces errors in your production, saving both time and money.

In the factory the accuracy is achieved by dosing mechanically, but use IQF instead and you avoid cleaning your dosing machine between 2 flavors, and switch immediately between recipes without cleaning.

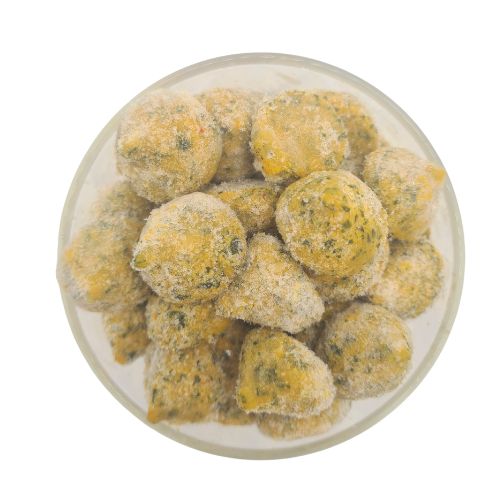

Complexity made easy

Now we are using juice or puree, we can start blending multiple ingredients. Combinations can be added as if they were a single ingredient, or we can even add complete recipes. The image you see here is an actual depiction of a curry madras pellet that is made of no less than 18 ingredients, ready to pop into your ready meal in the exact amount you need.

Plug & Play

Using IQF pellets becomes a plug & play solution that will enable you to see complex recipes as simple ingredients. You will be able to do more with your existing production capacity, and bring innovative products to your market fast, without heavy investments in new machinery.

The fast track to innovation

5 + 3 = 15 or more.

A doubtful statement mathematically, but it does make sense from a business perspective. Let us explain by using a simple example:

• You’re a food service provider and you offer 5 smoothies to your customers.

• Now put 3 jars with IQF pellets in your freezer, and on your price list, preferably with a catchy name… How about Smoothie Boosters?

• You can now sell 15 combinations by just blending 1 pellet in a smoothie, or a lot more if you let customers combine your Smoothie Boosters.

• Customers get more choices and a higher quality product, while the extra handling is negligible as there’s no extra washing, peeling, slicing…

• Thanks to the extra experience and the greater nutritional value, you can increase your markup.

Don’t be afraid to think out of the box! Customers are on the lookout for wild ideas, as long as they’re they’re clean, natural and healthy. How about Acerola, Spirulina, or Baobab?

The bottom line

IQF is booming. Don't be left out in the cold.

After reading all of the above, it shouldn’t come as a surprise that frozen foods in general, and the IQF market specifically, is in a serious uptrend right now. This growing demand and interest in IQF products is registered at a global level.

There still is discussion between the different market analysts though, but not in whether the market will continue to boom or not. They just don’t agree on how hard it will continue to grow exactly. This is what the analysts are saying:

Market Watch:

“In 2021, the IQF Vegetables and Fruits market was growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.”

__

Zion Market Research:

“Global IQF vegetable market expected to reach approximately USD 1,669 million in revenue by 2024, growing at a CAGR of around 6.67% between 2018 and 2024. Increasing population and growing preference toward frozen food are driving the IQF vegetable market growth globally.”

__

Fortune Business Insights:

“The global frozen food market size was USD 146.79 billion in 2019 and is projected to reach USD 185.28 billion by 2027, exhibiting a CAGR of 3.1% during the forecast period.”

https://www.fortunebusinessinsights.com/frozen-food-market-104138

In conclusion: Some things to remember

• Frozen can be fresher than fresh.

• Using IQF results in better nutritional values, less waste, and sometimes even less packaging.

• Turning ingredients into juice or puree opens up another world of possibilities.

• Consumers are willing to pay extra for innovative products, as long as they are clean, natural and healthy.

• IQF technology can help you to create innovations that would otherwise be too expensive or difficult to produce.

• Bringing innovation into your production by integrating IQF is a lot faster, easier, and cheaper than investing in new machinery and opening up complete new production lines.

• Many other companies are already doing this, and this trend will continue to rise.

How CUBE can help

CUBE has been a pioneer in IQF technology: Our first pellet line was set up more than 10 years ago. A decade of built-up experience over numerous custom developments for our clients provides us with a solid know-how into what works and what doesn’t when it comes to the integration of IQF technology in your food production pipeline.

Preparation of the purees can happen in different ways, depending on your specific needs: The classic way, by heating, or uncooked, with our in-house developed technology of cold milling. The latter can be made ready to eat with high pressure pasteurisation (HPP) to deliver a never heated end result with an unmatched amount of nutrients, flavor, color and taste.

This makes CUBE the ideal partner for your food company to take advantage of these extraordinary benefits, jumpstart your innovation trajectory, and get ahead of new market developments.

We look forward to discover

what we can develop together.

Don’t hesitate to get in touch: We will help you find the best matches between your product range and our existing solutions, or set our R&D specialists at work to develop a tailor made solution for your market:

Plug & Play

Check out our product finder for our broad range of readily available HPP Purees and IQF pellets which you can plug into your products very fast:

SHARE THIS REPORT: